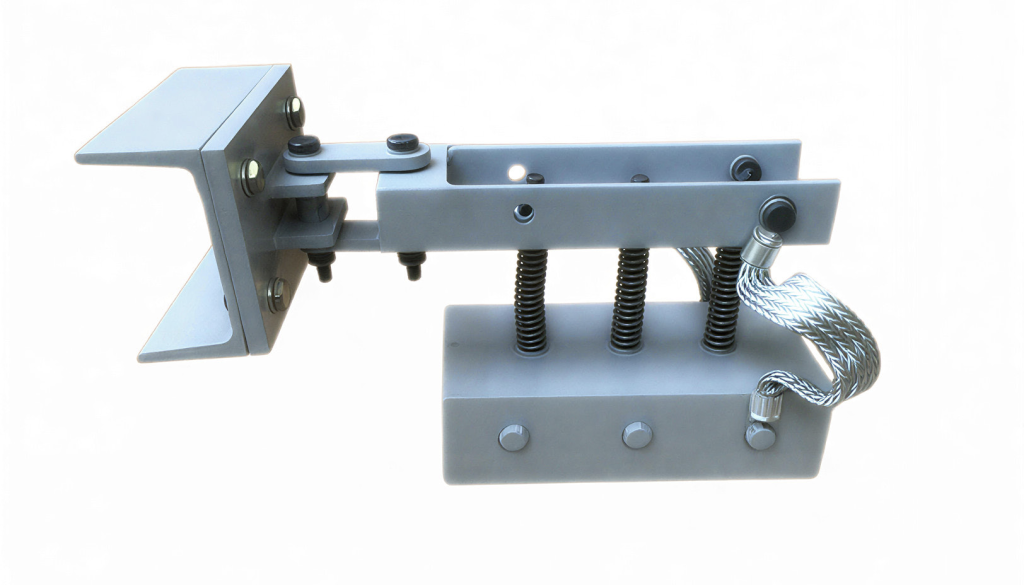

Pull Cord Switches

Pull Cord Switches are critical safety devices designed to ensure immediate emergency shutdown of belt conveyor systems during abnormal or hazardous conditions. Installed along both sides of the conveyor, these switches allow operators to stop the entire conveyor line instantly by pulling the wire rope from any point within the operating range.

Engineered for continuous operation in harsh industrial environments, our Pull Cord Switches feature a robust enclosure, a reliable tripping mechanism, and quick reset functionality, ensuring consistent performance and maximum safety for both equipment and personnel.

Application

1. Power plants

2. Cement industries

3. Steel plants

4. Mining operations

5. Bulk material handling systems

INDUSTRIAL DRUM HEATERS

Industrial Drum Heaters are designed to heat and maintain the temperature of viscous materials stored in drums, ensuring smooth flow and consistent processing. They are ideal for substances such as oils, chemicals, resins, waxes, adhesives, and lubricants, which require controlled heating to prevent solidification or viscosity-related handling issues.

Our drum heaters provide uniform heat distribution, energy-efficient performance, and easy installation, making them a reliable solution for industrial heating applications across multiple sectors.

Application

1. Chemical and process industries

2. Oil, lubricant, and resin handling

3. Pharmaceutical and food processing units

4. Manufacturing and packaging facilities

PULL CORD SWITCH

Pull Cord Switch is a safety device used on belt conveyor systems to stop the conveyor immediately in case of emergency. The switch is activated by pulling a rope (cord) installed along the conveyor length.

Technical Specifications |

Typical Value / Description |

Type |

Pull Cord Emergency Stop Switch |

Operation |

Latching / Manual Reset |

Actuation |

Pull on rope from either side |

Switching Mechanism |

Snap action |

Reset Type |

Manual reset lever |

Contact Configuration |

1NO + 1NC / 2NO + 2NC (model dependent) |

| TECHNICAL SPECIFICATIONS | TYPICAL VALUE / DESCRIPTION |

| Type | Pull Cord Emergency Stop Switch |

| Operation | Latching / Manual Reset |

| Actuation | Pull on rope from either side |

| Switching Mechanism | Snap action |

| Reset Type | Manual reset lever |

| Contact Configuration | 1NO + 1NC / 2NO + 2NC (model dependent) |

ANTI-COLLISION DEVICE

The anti-collision system is a safety device to avoid collision of two electric overhead Travelling cranes working on the same rails. For one pair of cranes two sets on anticollision system are required. Each set consist of an emitter / sensor module and a Reflector. The system works on the principal of retro reflective Infrared waves. It Consist of an emitter / sensor and a special reflector. The emitter emits the Infrared In The direction of the reflector. The reflector reflects these Infrared waves back to The sensor. The sensor senses the presence of these reflected Infrared waves and Activates an alarm signal and stop / reduce the speed of the cranes.

Technical Data |

Typical Value / Description |

Voltage supply |

110 vac/230 vac |

No. Of set points |

Single |

Contacts rating |

2 amps @ 220 vac |

Indication |

Led |

Device dimension |

180 x 145 x 55 mm |

Contact Configuration |

130 x 75 mm |

| TECHNICAL DATA | TYPICAL VALUE / DESCRIPTION |

| Voltage supply | 110 vac/230 vac |

| No. Of set points | Single |

| Contacts rating | 2 amps @ 220 vac |

| Indication | Led |

| Device dimension | 180 x 145 x 55 mm |

| Reflector dimension | 130 x 75 mm |

BELT SWAY SWITCH

Belt sway switch is a safety device installed on belt conveyors to monitor belt alignment and prevent damage due to belt deviation or excessive sway. When the belt’s edge deflects beyond a preset angle, the switch actuates and can signal an alarm or stop the conveyor to prevent mechanical damage, material spillage, and accidents.

Parameter 1 |

Typical Value / Description |

Operating Principle |

Tilt sensing via roller/lever contacting belt edge |

Action/Detection Angles |

First level alarm ~ 15–20° |

Operating Torque / Force |

~3.4–5.4 Nm (or ~75–100 N on some models) |

Reset Type |

Automatic reset spring-return when belt returns to normal |

Roller Mount |

Perpendicular to belt edge with small clearance |

Operating Temperature |

Typical: -20 °C to +60 °C (may vary by manufacturer) |

| PARAMETER 1 | TYPICAL VALUE / DESCRIPTION |

| Operating Principle | Tilt sensing via roller/lever contacting belt edge |

| Action/Detection Angles | First level alarm ~ 15–20° |

| Operating Torque / Force | ~3.4–5.4 Nm (or ~75–100 N on some models) |

| Reset Type | Automatic reset spring-return when belt returns to normal |

| Roller Mount | Perpendicular to belt edge with small clearance |

| Operating Temperature | Typical: -20 °C to +60 °C (may vary by manufacturer) |

PULL ROPE

Polyester Cable Pulling Rope Intended Use: Horizontal cable pulling with capstan winches or manual pull systems.

MODEL VARIANTS & DIMENSIONS |

Typical Value / Description |

Item No. |

CAI120 |

Rope Ø (mm) |

12 |

Length |

150 m |

Reel Basket Ø (mm) |

770 |

Internal Reel Width (mm) |

Ferrous gear or disc |

Weight (kg) |

~31.5 |

| MODEL VARIANTS & DIMENSIONS | TYPICAL VALUE / DESCRIPTION |

| Item No. | CAI120 |

| Rope $\varnothing$ (mm) | 12 |

| Length | 150 m |

| Reel Basket $\varnothing$ (mm) | 770 |

| Internal Reel Width (mm) | Ferrous gear or disc |

| Weight (kg) | ~31.5 |

MASTER CONTROLLER

Master Controller is a mechanical/electromechanical control unit used for remote operation and sequencing of heavy industrial equipment (e.g., EOT cranes, rolling mills, hoists). It typically uses cam-operated switches with selectable steps and contacts to provide precise control.

| ENCLOSURE & PROTECTION | TYPICAL VALUE / DESCRIPTION |

| Body Material | Sheet Steel or Aluminum Die Cast |

| Protection Rating | IP-44 / IP-54 (dust and splash-proof) |

| Mounting Position | Horizontal / Vertical |

ZERO SPEED SWITCH

Detects absence of motion (zero or low speed) of rotating equipment via pulse input or magnetic/inductive sensing and provides dry relay contact outputs for control / alarm / interlock.

| GENERAL TECHNICAL SPECIFICATIONS | TYPICAL VALUE / DESCRIPTION |

| Supply Voltage | AC 110–230 V or DC variants (6-36 VDC) |

| Speed Detection Range | 0 – 5000 RPM (varies by model & pulse configuration) |

| Output Contacts | multiple contacts (e.g., 2NO + 2NC) rated ~5 A @230 |

| Delay / Startup Timer | Adjustable (e.g., 1–30 s) to avoid nuisance trips |

| Enclosure Protection | IP65 (weatherproof) standard for many industrial versions |

| Mounting | Wall or DIN rail, depending on model |

| Speed Setting Method | Potentiometer or digital interface |

| Sensing Type | Inductive probe or magnetic sensor |

| Operating Temp. | Typically 0–60 °C (varies) |

INDUSTRIAL JOYSTICK CONTROLLER

The joystick controller is a manually operated control device used for precise directional control of machinery. It converts mechanical movement into electrical signals for controlling motors, actuators, or variable-speed drives.

| ELECTRICAL SPECIFICATIONS | TYPICAL VALUE / DESCRIPTION |

| Rated Voltage | 24 V DC (typical) |

| Rated Current | 5 A (max, per contact) |

| Contact Type | SPDT / DPDT (model dependent) |

| Switching Type | Momentary / Maintained |

| Contact Material | Silver alloy |

| Insulation Resistance | $\ge$ 100 M$\Omega$ at 500 V DC |

RESISTANCE BOX

Resistance Box is a precision electrical instrument used to provide a wide range of known resistance values by means of rotary switches or plug-type selectors. It is commonly used for testing, calibration, simulation, and laboratory experiments.

| ELECTRICAL SPECIFICATIONS | TYPICAL VALUE / DESCRIPTION |

| Resistance Range | 1 $\Omega$ to 10 M$\Omega$ (typical, configurable) |

| Resistance Steps | Decade type (1, 10, 100, 1k, 10k, etc.) |

| Accuracy | $\pm$0.1%, $\pm$0.5% or $\pm$1% (as per model) |

| Power Rating | 0.5 W to 1 W per resistor |

| Temperature Coefficient | $\pm$50 to $\pm$100 ppm/°C |

| Insulation Resistance | $\ge$ 100 M$\Omega$ at 500 V DC |

ELECTRO-HYDRAULIC THRUSTER

Electro-Hydraulic Thruster is a self-contained drive unit that converts electrical energy into linear mechanical motion through hydraulic pressure. It is widely used for operating drum brakes, disc brakes, gates, dampers, and lifting mechanisms.

| ELECTRICAL SPECIFICATIONS | TYPICAL VALUE / DESCRIPTION |

| Rated Voltage | 415 V AC ±10% |

| Frequency | 50 Hz |

| Phase | 3 Phase |

| Power Rating | 0.18 kW to 2.2 kW |

| Duty Class | S1 / S3 (as applicable) |

| Insulation Class | Class F |

DSL BUSBAR

The DSL Busbar System is an insulated conductor rail system designed for safe and continuous power transmission to moving equipment. It consists of PVC-insulated copper conductors, current collectors, joint assemblies, and mounting accessories.

| ELECTRICAL SPECIFICATIONS | TYPICAL VALUE / DESCRIPTION |

| Type | Down Shop Lead (DSL) Insulated Busbar |

| Application | EOT cranes, Hoists, Monorails, Conveyors |

| Rated Voltage | Up to 660 V AC |

| Rated Current | 40 A, 60 A, 100 A, 140 A, 200 A, 250 A |

| Rated Upto | 1600 DC |

| Number of Poles | 3P, 4P, 5P, 6P |

DSL BUSBAR

The DSL Busbar System is an insulated conductor rail system designed for safe and continuous power transmission to moving equipment. It consists of PVC-insulated copper conductors, current collectors, joint assemblies, and mounting accessories.

| ELECTRICAL SPECIFICATIONS | TYPICAL VALUE / DESCRIPTION |

| Type | Down Shop Lead (DSL) Insulated Busbar |

| Application | EOT cranes, Hoists, Monorails, Conveyors |

| Rated Voltage | Up to 660 V AC |

| Rated Current | 40 A, 60 A, 100 A, 140 A, 200 A, 250 A |

| Rated Upto | 1600 DC |

| Number of Poles | 3P, 4P, 5P, 6P |

CURRENT COLLECTOR

Current collectors are thin metallic foils used to conduct electrons between the external circuit and the active electrode material in rechargeable batteries.

| COPPER FOIL CURRENT COLLECTOR | TYPICAL VALUE / DESCRIPTION |

| Material | Electrolytic Copper (Cu ≥ 99.9%) |

| Application | Lithium-ion battery |

| Surface Treatment | Single-side / Double-side roughened or untreated |

| Crystal Structure | FCC |

| Thickness Range | 4 – 12 μm (common: 6, 8, 10 μm) |

| Density | 8.96 g/cm³ |

EARTH CURRENT COLLECTOR

Earth Current Collector (ECC) is a buried conductive assembly used in cathodic protection and earthing systems to collect and dissipate electrical current into the surrounding soil. It is commonly installed near pipelines, tanks, grounding systems, and DC traction systems.

| TECHNICAL SPECIFICATIONS | TYPICAL VALUE / DESCRIPTION |

| Rated Current Capacity | Up to 50 A (continuous) |

| Collector Material | High-conductivity copper (≥99.9%) |

| Copper Conductivity | ≥ 58 MS/m |

| Collector Length | 1 m – 6 m (customizable) |

| Copper Strip Size | 25 × 3 mm / 50 × 6 mm (typical) |

| Cable Size | 16 mm² – 70 mm² Cu |

WELDING DB

The Welding Distribution Board (Welding DB) is designed to safely distribute electrical power to multiple welding machines. It provides protection, isolation, and reliable power distribution in industrial environments.

| TECHNICAL SPECIFICATIONS | TYPICAL VALUE / DESCRIPTION |

| Rated Voltage | 415 V AC |

| Frequency | 50 Hz |

| Phase | 3 Phase + Neutral + Earth |

| Rated Current | 63 A / 100 A / 125 A / 200 A (as required) |

| Short Circuit Withstand | 25 kA (typical) |

| Incoming Supply | MCCB / Isolator |

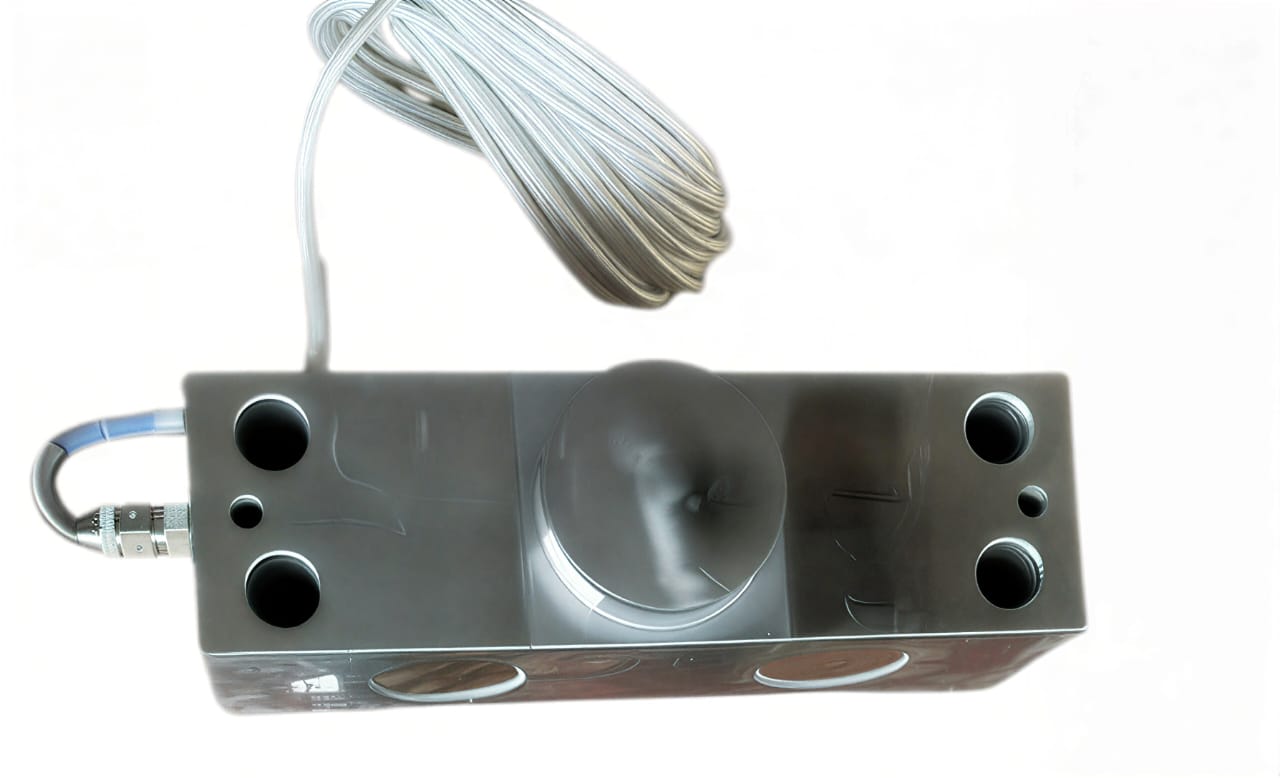

LOAD CELL

load cell is a transducer that converts applied mechanical force (weight) into a proportional electrical signal. Most industrial load cells use strain gauge technology.

| ELECTRICAL CHARACTERISTICS | TYPICAL VALUE / DESCRIPTION |

| Rated Output | 2.0 ± 0.2 mV/V |

| Zero Balance | ±1% of Rated Output |

| Input Resistance | 380 ± 10 $\Omega$ |

| Output Resistance | 350 ± 5 $\Omega$ |

| Insulation Resistance | $\ge$ 5000 M$\Omega$ (at 50 V DC) |

| Excitation Voltage | 5 – 12 V DC (Max 15 V DC) |

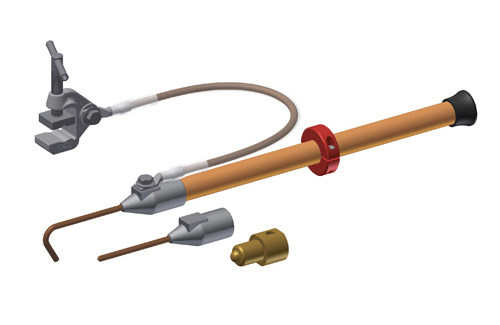

DISCHARGE ROD

Discharge Rod Belt Conveyor Systems / Bulk Material Handling Dissipates static electricity generated on moving conveyor belts to prevent sparks, shocks, fire, or damage to electronic equipment.

| TECHNICAL SPECIFICATIONS | TYPICAL VALUE / DESCRIPTION |

| Operating Principle | Static charge dissipation to earth |

| Operating Voltage | Passive device (no external power required) |

| Electrical Resistance | $\le$ 1 M$\Omega$ (to ground) |

| Earthing Connection | Copper earthing cable / lug provided |

| Belt Speed Compatibility | Up to 6 m/s |

EOT CRANE

Electric Overhead Travelling Crane Single Girder / Double Girder Material Handling Indoor / Outdoor Pendant / Radio Remote / Cabin Operated.

| CAPACITY & CLASSIFICATION | TYPICAL VALUE / DESCRIPTION |

| Safe Working Load (SWL) | 10 TON |

| Duty Class | IS 3177 / IS 807 / FEM / CMAA |

| Design Standard | IS 3177 & IS 807 |

| Temperature Range | -10°C to +50°C |

| Hoist Type | Wire Rope Hoist |

| Drum | Seamless machined steel drum |

CHAIN BLOCK MANUAL CHAIN HOIST

Chain Block is a manually operated lifting device used for vertical lifting of loads in workshops, construction sites, warehouses, and industrial plants. It operates using a hand chain mechanism with hardened load chains for safe and smooth lifting.

| TECHNICAL SPECIFICATIONS | TYPICAL VALUE / DESCRIPTION |

| Product Type | Manual Chain Block / Chain Pulley Block |

| Lifting Capacity | 0.5 / 1 / 2 / 3 / 5 / 10 / 20 Ton (as applicable) |

| Standard Lifting Height | 3 m (optional: 6 m, 9 m, 12 m or as required) |

| Load Chain Material | Alloy Steel, Grade 80 |

| Load Chain Size | As per capacity |

| Hand Chain Material | Galvanized Steel |

HEAT RESISTANT FIRE SLEEVE

Heat Resistant Fire Sleeve is a protective tubular sleeve designed to shield hoses, cables, pipes, and wiring from extreme heat, flame exposure, molten metal splash, and abrasion. It is typically constructed from fiberglass braid and coated with high-temperature silicone rubber.

| TECHNICAL DATA | TYPICAL VALUE / DESCRIPTION |

| Continuous Working Temperature | -54°C to +260°C |

| Short-Term / Intermittent Temperature | Up to 1650°C (direct flame exposure) |

| Melting Point (Fiberglass) | > 1000°C |

| Thermal Conductivity | Low |

| Flame Resistance | Self-extinguishing |

| Heat Radiation Reduction | Up to 90% |

WAVE SLING

Wave Sling is an industrial material flow / clog detection device designed to detect blockage, choking, or abnormal material flow in chutes, hoppers, conveyors, and transfer points. It operates by sensing vibration/wave changes caused by material movement.

| TECHNICAL SPECIFICATIONS | TYPICAL VALUE / DESCRIPTION |

| Operating Principle | Vibration / Wave sensing |

| Supply Voltage | 230 VAC ±10% / 110 VAC (optional) |

| Frequency | 50 / 60 Hz |

| Power Consumption | $\le$ 5 W |

| Output Contact | 1 NO + 1 NC (SPDT relay) |

| Contact Rating | 5 A @ 230 VAC |

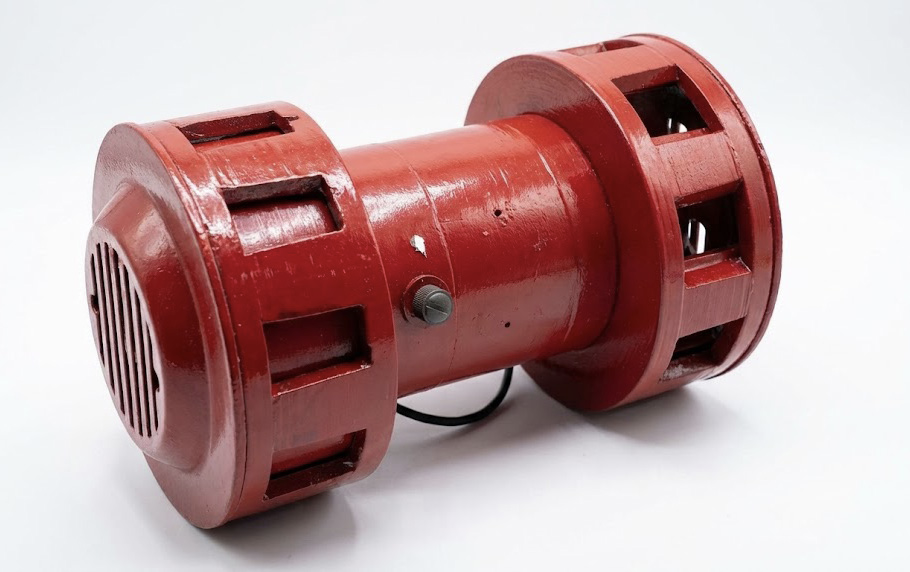

INDUSTRIAL HOOTER

Industrial Hooter is an electrically operated audible warning device designed to produce a loud and continuous sound for alarms, emergency signaling, machine status indication, and process alerts in industrial environments.

| TECHNICAL DATA | TYPICAL VALUE / DESCRIPTION |

| Type | Electro-mechanical / Electronic Hooter |

| Rated Voltage | 24 V DC / 110 V AC / 230 V AC (as required) |

| Voltage Tolerance | ±10% |

| Frequency | 50 / 60 Hz (AC models) |

| Sound Output | 90 dB to 120 dB @ 1 meter |

| Sound Type | Continuous / Intermittent |

INDUSTRIAL SOCKET

Industrial plugs and sockets are high-performance electrical connectors designed for industrial environments, widely used in factories, construction sites, mines, and similar locations. Suitable for harsh conditions, they feature high protection ratings such as IP44 and IP67 for water and dust resistance. Available in various specifications, including 16A, 32A, and 63A, they meet different equipment power requirements to ensure safe and stable operation.

| TECHNICAL DATA | TYPICAL VALUE / DESCRIPTION |

| Rated voltage | AC/DC |

| AC | 24, 42, 110, 127, 220, 240, 380, 415, 660V |

| DC | 24, 110, 220, 440V |

| Rated current | 16, 32, 63, 125A |

| Rated frequency | 50-60Hz |

| Drum | Seamless machined steel drum |

HYDRAULIC FITTING

Hydraulic fittings are precision-engineered components used to connect hoses, tubes, and pipes in hydraulic systems to ensure leak-free fluid transfer under high pressure.

| TECHNICAL SPECIFICATIONS | CONNECTION STANDARDS OPTIONAL AS PER REQUIREMENT |

| TYPE | BSPP / BSPT (British Standard Pipe) |

| Straight fitting | JIC 37° Flare (SAE J514) |

| Elbow fitting (45°, 90°) | ORFS (SAE J1453) |

| Tee fitting | ORFS (SAE J1453) |

| Reducer / Adapter | NPT / NPTF |

| Bulkhead fitting | DIN 2353 |

HYDRAULIC HOSE

High-pressure hydraulic hose designed for conveying hydraulic fluids such as mineral oils, lubricating oils, water-glycol, and emulsions in industrial and mobile hydraulic systems.

| TECHNICAL SPECIFICATIONS | TYPICAL VALUE / DESCRIPTION |

| Nominal Bore | 6 mm to 50 mm (¼” to 2″) |

| Working Pressure | Up to 420 bar (depends on hose type) |

| Burst Pressure | Minimum 4 × Working Pressure |

| Vacuum Rating | Up to -0.9 bar |

| Temperature Range | -40°C to +100°C (up to +120°C intermittent) |

| Fluid Compatibility | Hydraulic oil, mineral oil, water-glycol |

MOTION SENSOR

The Motion Sensor is a Passive Infrared (PIR) based device designed to detect movement of human bodies or warm objects within a defined area. It senses changes in infrared radiation and provides an electrical output for automation, security, lighting control, and industrial applications.

| TECHNICAL SPECIFICATIONS | TYPICAL VALUE / DESCRIPTION |

| Sensor Type | Passive Infrared (PIR) |

| Detection Range | 6–12 m (adjustable) |

| Detection Angle | 90° – 180° (model dependent) |

| Supply Voltage | 12–24 V DC / 110–240 V AC |

| Power Consumption | $\le$ 1 W |

| Output Type | Relay / NPN / PNP (model dependent) |

SMOKE SENSOR

Smoke Sensor is a device designed to detect the presence of smoke particles in the air and generate a switch or alarm output when smoke is present. It is commonly used in fire detection and facility monitoring systems. The sensor does not detect gas, heat, or flame, only smoke.

| TECHNICAL SPECIFICATIONS | TYPICAL VALUE / DESCRIPTION |

| Condition Monitored | Smoke |

| Type | Switch-type smoke detector |

| Operating Voltage (Nominal) | 12 VDC or 24 VDC |

| Voltage Range (Min–Max) | 8.5 V to 35 V |

| Max Standby Current | ~50 $\mu$A average |

| Max Alarm Current | ~20 mA (12 V), ~23 mA (24 V) |

ELECTROMAGNETIC FLOW METER

Electromagnetic flow meters work on Faraday’s Law of Electromagnetic Induction. When a conductive liquid flows through a magnetic field, a voltage proportional to the flow velocity is induced and measured by electrodes.

| TECHNICAL SPECIFICATIONS | TYPICAL VALUE / DESCRIPTION |

| Measuring Principle | Electromagnetic |

| Flow Velocity Range | 0.1 to 10 m/s |

| Accuracy | $\pm$0.5% of reading ($\pm$0.2% optional) |

| Repeatability | $\pm$0.1% |

| Nominal Diameter | DN 15 to DN 2000 (1/2″ to 80″) |

| Measuring Range | Bi-directional |

WINCH MACHINE

Winch machine is a mechanical device used for pulling, lifting, or lowering loads by winding a wire rope or chain around a rotating drum. It is widely used in industries such as mining, construction, marine, material handling, and conveyor systems.

| TECHNICAL SPECIFICATIONS | TYPICAL VALUE / DESCRIPTION |

| Type | Electric / Hydraulic / Manual |

| Rated Load Capacity | 1 Ton to 50 Tons (customizable) |

| Line Pull (First Layer) | As per rated capacity |

| Line Speed | 5 – 30 m/min (no load / full load) |

| Drum Capacity | 50 – 500 m wire rope |

| Drum Diameter | 200 – 800 mm |

SPRING BALANCER

Spring Balancer is a mechanical device designed to suspend tools and loads, automatically balancing their weight to reduce operator fatigue and improve safety. It allows smooth vertical movement and holds the load at any desired position.

| TECHNICAL SPECIFICATIONS | TYPICAL VALUE / DESCRIPTION |

| Type | Spring-loaded mechanical balancer |

| Load Capacity Range | 0.5 – 120 kg (model dependent) |

| Stroke / Cable Travel | 1.0 – 2.5 meters |

| Suspension Type | Steel wire rope |

| Cable Diameter | 2.5 – 5 mm |

| Body Material | Die-cast aluminum / steel |

INDUSTRIAL MANCOOLER FAN

Heat Resistant Fire Sleeve is a protective tubular sleeve designed to shield hoses, cables, pipes, and wiring from extreme heat, flame exposure, molten metal splash, and abrasion. It is typically constructed from fiberglass braid and coated with high-temperature silicone rubber.

| TECHNICAL SPECIFICATIONS | TYPICAL VALUE / DESCRIPTION |

| Fan Model | CAI-750 |

| Type Of Fan | INDUSTRIAL MANCOOLER FAN |

| Rated Speed ( In RPM) | 1400 |

| Impeller Diameter | 750MM |

| Type Of Impeller | FIXED PITCH |

| No. of Blades | 06 NOS |

| Material of Construction of Fan Guard | IS – 2062 M.S |

| Material of Construction of Impelle | Cast Aluminium Alloy IS 617 |